- Innovative cleaning technologies significantly enhance the safety and operational efficiency of pipelines while reducing risks.

- Eco-friendly cleaning methods are crucial for achieving modern sustainability goals and complying with environmental regulations.

- Routine maintenance and predictive monitoring minimize downtime, cut costs, and extend pipeline life.

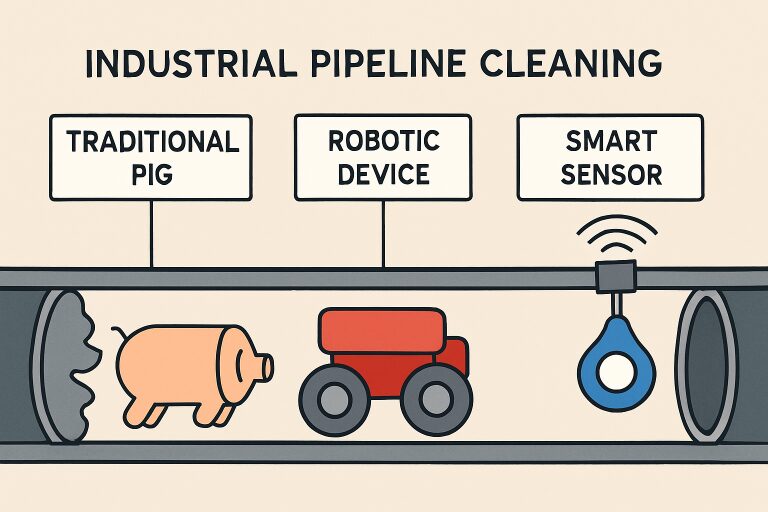

- Traditional Pipeline Cleaning Methods

- Advancements in Intelligent Pigging

- Robotic and Automated Cleaning Systems

- Eco-Friendly Cleaning Solutions

- Laser Cleaning Technology

- Predictive Maintenance and Digital Monitoring

- Conclusion

Maintaining the cleanliness and proper functioning of industrial pipelines is a cornerstone of safe and efficient operations across various sectors, including oil and gas, chemical processing, and water utilities. By investing in advanced pigging equipment for optimal pipeline maintenance and inspection, companies are better equipped to remove accumulated debris and contaminants that can compromise flow rates and lead to operational hazards.

The evolution of pipeline cleaning methods reflects growing concerns about safety standards, system longevity, and environmental stewardship. Today’s technologies offer far more than just surface-level cleaning, incorporating intelligent diagnostics and eco-friendly strategies that align with modern regulatory pressures and sustainability targets. As industries strive to cut costs and increase uptime, the integration of innovative pipeline cleaning technology becomes a strategic necessity.

Traditional pipeline maintenance, once focused strictly on the physical removal of blockages, now encompasses a holistic approach. From pipeline integrity management to advanced data analysis and automation, operators can leverage a combination of traditional and modern methods for optimal results. Each approach—whether mechanical, chemical, robotic, or data-driven—serves to reduce corrosion, minimize unplanned downtime, and extend the lifecycle of critical infrastructure.

As regulations on emissions and waste management tighten globally, pipeline operators must consider the environmental impact of their chosen cleaning methods. This evolution in regulatory focus drives the adoption of technologies that are not only powerful and efficient but also environmentally conscious and sustainable.

The most enduring method of pipeline cleaning is mechanical pigging—a process that uses purpose-designed devices known as “pigs.” These cleaning tools physically traverse the interior of pipelines, scraping away wax, scale, and other residues that can obstruct flow or cause corrosion. Traditional pigging remains a foundational process, especially for straight pipeline segments and large-scale operations. However, mechanical approaches have limitations in their ability to detect hidden anomalies and adapt to complex pipeline geometries.

Intelligent pigging enhances pipeline inspection far beyond traditional cleaning methods. Outfitted with sophisticated sensors, these “smart” pigs gather critical real-time data concerning corrosion, wall thickness changes, pits, cracks, and deformation. By transmitting this information as they travel through the pipeline, intelligent pigs enable maintenance teams to address issues before they escalate into emergencies. The result is a proactive maintenance strategy that not only ensures regulatory compliance but also drastically reduces the possibility of leaks and failures, saving millions in repairs and lost product.

Robotic cleaning systems are rapidly becoming the industry standard for pipelines that operate in challenging or hazardous environments. Unlike conventional pigs that require shutdowns and manual recovery cycles, robotic cleaners can be deployed while the pipeline remains operational. Equipped with cameras and adaptable cleaning heads, these robots deliver consistent cleaning results and detailed inspections, even in the most inaccessible or intricate sections of pipelines. Automation brings significant cost savings through reduced labor requirements and shorter downtime windows, boosting both safety and operational efficiency.

As environmental sustainability comes to the forefront, pipeline operators are turning to green cleaning agents that minimize ecological impact without sacrificing performance. Biodegradable surfactants, enzyme-based solutions, and integrated water recycling systems are at the core of these eco-friendly innovations. These solutions effectively break down organic residues and hydrocarbons, enabling safe disposal and minimizing chemical exposure to the surrounding environment. In addition, regulatory agencies increasingly mandate such sustainable approaches, making green cleaning both a compliance imperative and a corporate responsibility.

Laser technology introduces a non-contact, non-abrasive method for eliminating corrosion, scale, and contaminants from pipe interiors. By focused laser ablation, operators can clean surfaces thoroughly without physical wear or residue. This approach minimizes pollution, reduces resource consumption, and offers rapid deployment—particularly valuable for high-value or delicate pipelines. As industries push for cleaner processes, laser cleaning provides a new paradigm in efficiency, precision, and environmental stewardship.

Integrating digital monitoring and predictive analytics with pipeline cleaning unlocks new levels of operational intelligence. Advanced sensors embedded within pipelines monitor conditions such as flow rate, temperature, vibration, and internal cleanliness in real time. The data feeds into predictive maintenance algorithms, enabling operators to identify emerging issues and optimize cleaning schedules accordingly. This not only maximizes pipeline uptime but also extends asset life and ensures compliance with legislative requirements.

The adoption of innovative pipeline cleaning technologies has evolved from being a competitive edge to an essential requirement for ensuring safety, extending infrastructure lifespan, and meeting growing environmental expectations. Today’s advanced systems integrate proven traditional techniques with cutting-edge robotics capable of navigating complex interiors, as well as eco-friendly cleaning agents that minimize ecological impact. Real-time digital monitoring and data analytics now allow operators to detect issues early, optimize maintenance schedules, and reduce operational risks. For pipeline operators aiming to excel in a highly regulated and demanding industry, investing in these modern technologies provides a clear path toward more reliable, efficient, and sustainable operations.